Dilatation seals, also commonly referred to as expansion joints or expansion seals, are vital components used in engineering and construction to accommodate the movement and expansion of various structures, particularly in buildings, bridges, pipelines, and other infrastructure systems. The primary function of dilatation seals is to provide flexibility and prevent damage caused by thermal expansion, seismic activity, structural settlement, or other dynamic forces.

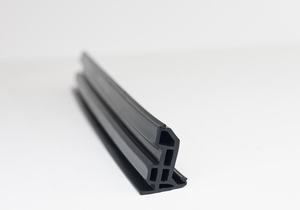

These seals are typically made from a variety of materials, including rubber, neoprene, silicone, metal, or a combination of these materials, depending on the specific application and environmental conditions. Each material offers different properties such as elasticity, durability, chemical resistance, and temperature tolerance, which are crucial factors in selecting the appropriate seal for a given project.

The design of dilatation seals varies depending on the requirements of the structure and the expected movements it will experience. Common types of dilatation seals include:

- Rubber Expansion Joints: These are typically made from synthetic rubber compounds and are designed to accommodate large movements in multiple directions. They are often used in bridges, highways, and buildings to absorb vibration and movement caused by thermal fluctuations and seismic activity.

- Metal Bellows Expansion Joints: These consist of a series of convoluted metal bellows that allow for axial, lateral, and angular movements. They are commonly used in piping systems to compensate for thermal expansion and contraction, as well as to absorb vibrations and noise.

- Modular Expansion Joints: These are prefabricated units consisting of steel or rubber modules that are bolted together to form a continuous seal. They are frequently used in bridge construction to accommodate large movements and provide a smooth driving surface for vehicles.

- Compression Seals: These seals are typically made from neoprene or rubber and are used to fill the gaps between adjacent concrete or steel structures. They accommodate limited movements and provide a watertight seal to prevent the ingress of moisture and debris.

- Sliding Plate Expansion Bearings: These consist of steel plates that are sandwiched between layers of low-friction material, such as PTFE (polytetrafluoroethylene). They allow for longitudinal movements in bridge structures while providing support and stability.

Regardless of the type, dilatation seals must be carefully engineered and installed to ensure proper functionality and longevity. Factors such as the magnitude of movement, environmental conditions, structural loads, and traffic considerations must be taken into account during the design and installation process.

In addition to their functional role, dilatation gaskets also play a crucial role in preserving the structural integrity and longevity of infrastructure systems. By reducing the stresses and strains caused by movements and dynamic forces, these seals help minimize maintenance requirements, extend the lifespan of structures, and enhance overall safety and performance.