Aluminium rubber, also known as aluminum rubber or aluminum silicone rubber, is a composite material that combines the properties of aluminum and rubber or silicone. This unique combination offers a range of advantageous characteristics, making it suitable for various applications across industries such as automotive, aerospace, electronics, and construction.

The composition of aluminum rubber typically involves embedding aluminum particles or flakes within a rubber or silicone matrix. The aluminum component provides several beneficial properties, including high thermal conductivity, electrical conductivity, corrosion resistance, and lightweight construction. Meanwhile, the rubber or silicone matrix offers flexibility, resilience, and vibration damping properties.

One of the primary advantages of aluminum rubber is its excellent thermal conductivity. This property allows the material to efficiently transfer heat away from components, making it ideal for heat dissipation applications. In electronic devices such as smartphones, computers, and LED lights, aluminum rubber can be used as a thermal interface material to enhance heat management and improve device performance and reliability.

Additionally, the electrical conductivity of aluminum rubber makes it suitable for electromagnetic interference (EMI) shielding applications. By effectively blocking or diverting electromagnetic radiation, it helps prevent interference with sensitive electronic components, thereby enhancing the performance and longevity of electronic devices.

Moreover, aluminum rubber’s corrosion resistance makes it suitable for outdoor and harsh environments where exposure to moisture, chemicals, or other corrosive agents is a concern. This property extends the lifespan of components and structures while reducing maintenance requirements.

Furthermore, the lightweight nature of aluminum rubber contributes to overall weight reduction in applications such as automotive and aerospace engineering. By replacing heavier materials with aluminum rubber composites, manufacturers can achieve fuel efficiency improvements in vehicles and enhance the payload capacity of aircraft.

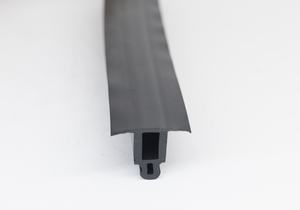

In the construction industry, aluminum rubber finds application in sealing and insulation materials, providing both weatherproofing and thermal insulation properties. Its flexibility allows for easy installation around irregular shapes and surfaces, ensuring effective sealing and insulation in various building structures.

Overall, the combination of aluminum and rubber or silicone in aluminum gaskets composites offers a versatile solution with a wide range of applications, contributing to improved performance, durability, and efficiency across various industries. Ongoing research and development continue to explore new formulations and applications for this innovative material.